The 6-Second Trick For 24hr Media

Table of ContentsMore About 24hr Media24hr Media - QuestionsSome Of 24hr MediaFascination About 24hr MediaThings about 24hr Media

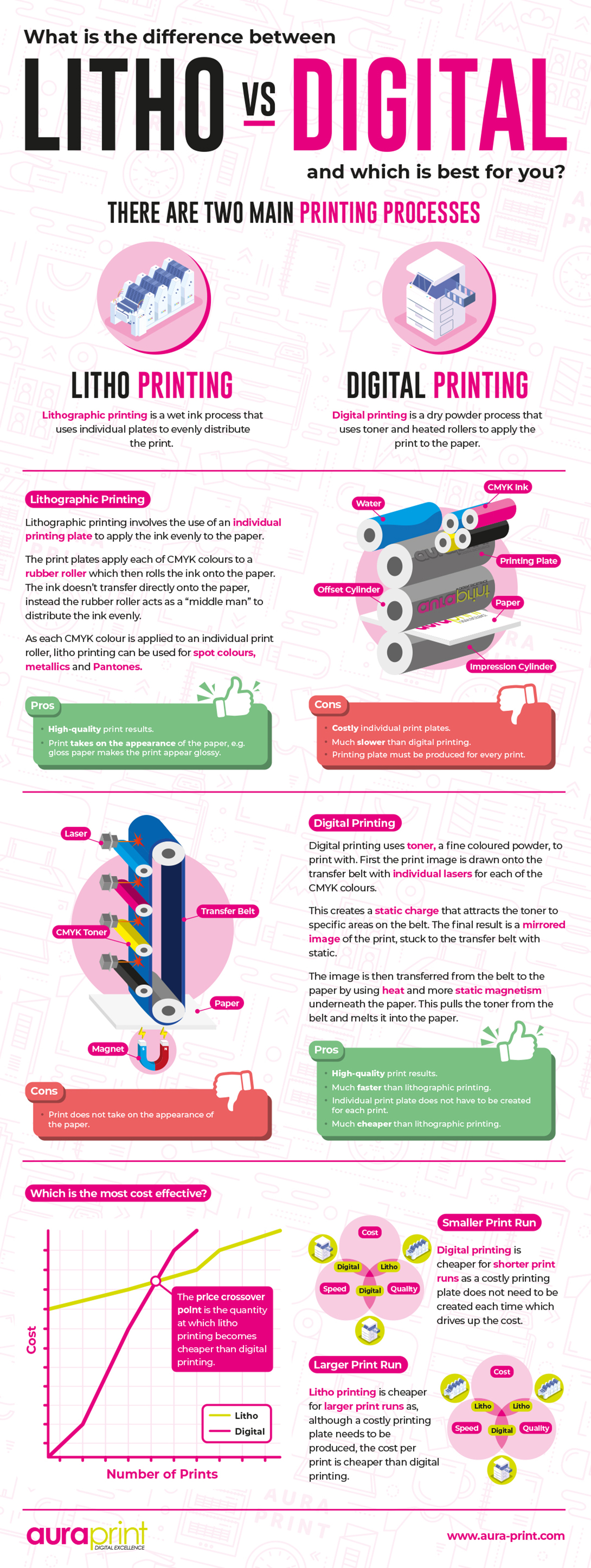

Offset, gravure printing and flexography are one of the most common kinds of conventional printing in the packaging space and each entails moving the picture from a plate to the surface. To do this, first home plate needs to be created, and it is the development of these plates that take some time, and cost money.According to PMMI, digital printing permits brands and makers to react quickly to consumer needs while enhancing the supply chain, decreasing warehousing expense and waste, and delighting in faster time to market. That all sounds great, however exactly how does this innovation do all that? The major differentiator of these modern technologies is that there are no set-up charges and no plates with electronic printing.

According to Wikipedia, the best difference in between digital printing and typical methods such as lithography, flexography, gravure, or letterpress is that there is no need to replace printing plates in electronic printing, whereas in these analog printing methods the plates are continuously replaced. This leads to quicker turn-around time and lowers cost when using digital printing.

Digital printing is extremely versatile, so it's easy to make changes to the package style rapidly. It all goes back to the plates.

The Best Strategy To Use For 24hr Media

More supply can suggest more waste later on. With conventional printing methods, short-run printing is simply not possible. Due to the fact that a fantastic style can make or break your item, electronic printing consistently creates top quality, clear and colorful graphics each time. Digital printing on flexible bags includes the brilliant, vibrant, and exact graphics that almost beckon consumers to connect and touch them.

Filling ... Are you familiar with the advantages of electronic printing? Both balanced out and digital printing have their location in the printing industry.

In this short article, we will certainly go over the benefits of electronic printing to help you much better comprehend if digital printing is simply what you require. Simply put - digital printing prints material directly onto the paper. It eliminates some steps required in balanced out printing, like developing steel plates. Inkjet printers use little nozzles to spray beads of ink onto the substrate.

The Ultimate Guide To 24hr Media

As electronic printing constantly advances, it provides much more opportunities and higher output high quality every day. In some instances, the print top quality can be as high as to balance out printing.

For countered printing, if any kind of error goes undetected prior to creating the plates, there will be a high cost of developing a new one. With digital printing, this is not the case (Small Volume Packaging). Everybody constantly hopes there will certainly be no errors, recognizing the cost of remedying them if they happen is constantly an excellent idea.

This implies every solitary item will certainly look the exact same, so the possibility you will need to discard any one of them as a result of inconsistencies is low. Given that a proofing sample is published on the very same device as the product itself, shade proofing is extremely accurate. Any kind of issues with shade will show up on the evidence, and thus it will be possible to alter it before publishing the entire run.

More About 24hr Media

Digital printing, on the other hand, needs very little configuration. There are less pre-press treatments, so the initial configuration time is dramatically reduced. Consequently, turn-around is visibly quicker. Your order can be refined as quickly as you submit it. This is excellent when you remain in a rush to obtain your published products.

This indicates even more demands for electronic on-demand print production. Every consumer appreciates an individualized message. Cost-efficient, smaller sized sets enable organizations to tailor each order.

Digital printing is the ideal option for variable information printing, like customized codes and addresses on direct mail. With digital printing, it is much less troublesome to make last-minute adjustments to your layout. In some cases the most effective type of communication is visit site not electronic. In these situations, relying upon electronic printing can make certain these orders have a very little environmental influence.

The 7-Minute Rule for 24hr Media

There is additionally no requirement to clean up the plates after printing. The benefits of electronic printing consist of that there is no waste from additional or remaining ink, paper, or chemicals because just what's required gets published. - for very brief runs, electronic printing is the way to go, undeniably.

Gone are the days of complicated configurations and lengthy turnaround times - electronic printing has actually revolutionised the print industry. The printing globe has come a long method because the days of Gutenberg's printing press. The new typical is structured procedures and economical services for printing onto virtually anything you can believe of.